History

Buster aluminium boats are manufactured at Inha Works in Ähtäri, Finland, where metal has been worked for the past two centuries. The story of the foundry village dates back to 1841, while boat production along the Inhanjoki river began 130 years later. Accordingly, Inha Works is celebrating its 180th anniversary, as well as the 45th anniversary of Buster aluminium boats, in 2021.

The history of Inha Works began in 1841, when justice Erik Gustaf Roschier, owner of the Inha sawmill and grain mill, was granted permission by the governor to manufacture iron on the banks of the Inhanjoki river. Industrial activity began in earnest 10 years later, when the iron mill began processing lake ore and bog ore into iron. The backer for the project was Gustaf August Wasastjerna, who had studied ironworking in Sweden and was the son of the Östermyra ironworks baron in Seinäjoki.

Industrial activity gained real momentum in 1884, when renowned industrialist August Nilsson Keirkner began to develop the factories and built a steam sawmill, a steel foundry, a horseshoe workshop, and a bolt and rivet workshop. Forged products continued to be manufactured in Inha to this day, only 170 years later, the historic black iron mill has been transformed into the equipment hall for Buster’s largest models.

Aluminium introduced for building boats in 1955

A subplot in the long history of boat production at Inha Works began in the 1950s at another ironworks, Kellokoski in Tuusula. In 1953, on the initiative of Per-Håkan Carlander, Kellokoski Works began manufacturing Kello aluminium boats. Using “light metal,” as it was referred to at the time, to manufacture boats was a revolutionary idea in the era of wooden boats. Carlander had travelled to the United States to study the techniques required for using aluminium.

These durable and carefree aluminium boats rapidly gained popularity: the first Kello 1 model, measuring just over three metres in length, was unveiled to the public in October 1955, and in the following year, just one shy of 800 boats were made. In total, almost 10,000 Kello aluminium boats of different sizes were sold.

The stories of the two factories specialising in metal processing came together in 1973, when Fiskars decided to move the production of aluminium boats from Kellokoski to Inha. Ownership of Inha Works had transferred from Keirkner to Fiskars already in 1917, and Kellokoski Works was acquired by Fiskars in 1963.

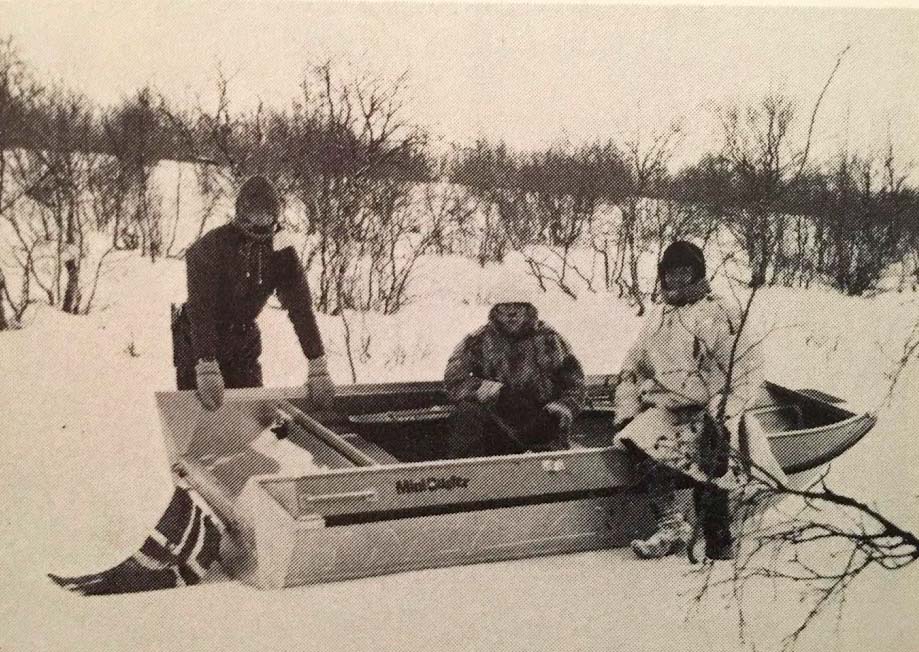

Production moved entirely to Ähtäri in 1976, and the two boat models were renamed the Fiskars 12 and Fiskars 14. The following year, these in turn became the 3.6-metre Mini Buster and 4.15-metre Buster.

Popularity of aluminium boats takes off in the late 1970s

The popular Buster models rapidly enhanced the reputation of aluminium boats in Finland, Sweden and Norway. In 1977, the market share of aluminium boats in the Nordic countries was only around two percent. By 1979, Fiskars could state that “aluminium boats had made a breakthrough in the Finnish and Scandinavian markets through strong marketing.” By the early 1980s, Buster's market share in Finland had risen to more than 30 percent.

Altogether more than 130,000 Buster and Kello aluminium boats have been manufactured over the years, and most of these are still in use. Even older Kello models from the 1950s are still on the water in large numbers.

Under Fiskars ownership, Inha Works had a wide range of production, including sheet metal cabinets, hinges and railway couplings. In the 21st century, this other production has been gradually discontinued – hinge manufacturing, for example, was transferred to Abloy – and the old ironworks area has focused on developing the production of aluminium boats.

Yamaha outboards and electronics fully integrated with Buster boats

The Fiskars era in Ähtäri ended in 2016, when Inha Works was acquired by Yamaha Motor, one of the world’s leading boating product companies. The new owner has over 50,000 employees around the world and annual net sales of approximately EUR 11 billion (2020).

Under Yamaha ownership, the boat, outboard and these days essential electronics have been integrated into the most complete package possible from the customer's point of view. In practice, this means that new models are designed to be paired with specific Yamaha outboards, and with the exception of the smallest models, standard equipment includes our own Buster Q infotainment system - a user interface for our state-of-the-art boats. For the customer, all this makes boating even easier and more comfortable.

The latest development step is the installation and trial running of outboards already at the factory. This phase has traditionally been done only at the dealer's premises before the boat is handed over to the customer. Although this is a significant change from the perspective of the boat manufacturer and dealer, it is not directly visible to the customer – only indirectly in terms of reliability and speed of service.

At the beginning of the 2020s, Inha Works is responsible for annual net sales of approximately EUR 70 million with around 125 employees working at the production plant in Ähtäri, which has an annual production capacity of more than 5000 boats.

Main picture: Inha Works in the early 1900s. Photo: G. A. Stoore / Museum of Central Finland